News & Events

News & Events

- Lecture #1 under NCB Distinguished Lecture Series on Novel Approaches in Cement Production - Coupling Materials Efficiency, Manufacturing Approaches and Decarbonization on 28th February 2025, Timings: 1100hrs

- Advertisement No. C/08/2024(02) - Written Test/Personal Discussion (11th Nov 2024) - POSTPONED

- NCB IC Event: Innovate Youth: Building Tomorrow's Entrepreneurs.

Consultancy services for getting NABL Accreditation as per ISO/IEC 17025:2017

Notice on Public Grievance

NCB – CCE EVENTS / Forthcoming Training Programmes

Proficiency Testing Schemes

Corrigendum - Compassionate Appointment in NCB for Group “C” & “D

Compassionate Appointment in NCB for Group “C” & “D

NCCBM to host 17th International Congress on Chemistry of Cement (ICCC) in 2027 in New Delhi

Life Cycle Assessment Studies

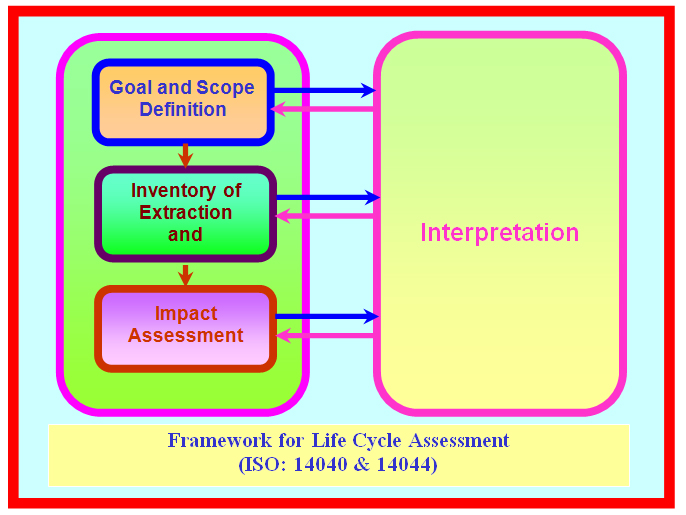

Life Cycle Assessment (LCA) is fast emerging as an environmental management tool adopted worldwide, to identify priorities for improvements in process operations, product design, alternative materials development and product substitution to meet the twin objectives of optimal resource utilization and sustainable development. Cement producers the world over, today are developing rigorous methodologies to appropriately utilize this tool to reach/retain their competitive position in the global market.

LCA study for cement sector was carried out in 2005-06 for the first time by NCB, under the aegis of Ministry of Environment and Forests, Govt. of India. NCB had evaluated input & output in terms of thermal energy and electrical energy, raw materials and emissions starting from mining to dispatch of cement for four major cement plants in different zones. The impact analysis in terms of global warming potential (GWP), acidification potential (AP), resource depletion (RD) and land use (LU) etc. was carried out to identify and improve the environmental parameters for individual processing units. This study has been completed from cradle to gate. In order to complete the whole life cycle, i.e. from gate to grave, LCA study for Construction Industry-Concrete was again sponsored by MoEF. NCB has evaluated the environmental impacts from different phases of four commercial buildings, two RMC plants and concrete road situated in different geographical locations. Various alternate paths for environment improvements were analyzed on the basis of five impact categories namely GWP, AP, resource conservation etc. LCA studies were also carried out for cement plants using alternate fuels and steel re-rolling mills sector