News & Events

News & Events

- Corrigendum-Upgradation of the Industrial Shed in NCB Campus, Ballabgarh, Haryana on EPC Mode

- Tender Notice-Upgradation of the Industrial Shed in NCB Campus, Ballabgarh, Haryana on EPC Mode

- NCB IC Event: Innovate Youth: Building Tomorrow's Entrepreneurs.

Consultancy services for getting NABL Accreditation as per ISO/IEC 17025:2017

Notice on Public Grievance

NCB – CCE EVENTS / Forthcoming Training Programmes

Proficiency Testing Schemes

NCCBM to host 17th International Congress on Chemistry of Cement (ICCC) in 2027 in New Delhi

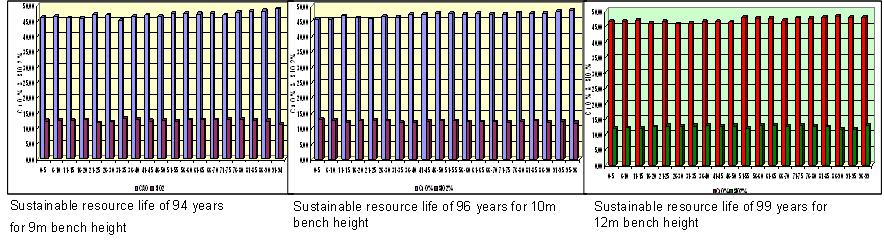

Strategy Planning and Sensitivity Analysis for Resource Optimization

The optimization and strategic planning for management of a large open pit limestone mine having a life of several years is an enormous and complex task. Strategic planning for mine optimization is carried out basically to enhance the quarry life with minimum generation of waste keeping in view the two main objectives (i) optimal grade of limestone and its production, a mine can produce up to the life of the deposit and (ii) optimization based on grade constraints keeping the consideration of alternative raw mix designs based on cheaper fuel and additives.

NCB has acquired RM Scheduler and Multimine Scheduler software for limestone resource optimization. With the help of these softwares optional mine scheduling and blending solutions for requirement of ROM limestone at various raw mixes scenario can be generated very quickly and reviewed for long term resource strategy planning and sensitivity analysis. It allows selection of optimized scheduling based on sensitivity analysis by change in grade, change in chemical parameters such as CaO, SiO2, Al2O3, Fe2O3, alkalies, sulphates etc., pit shape/slope, number of benches, bench height, production target etc.

Strategically resource planning and sensitivity analysis has been carried out to arrive at an optimum economical extraction sequence with minimum quality variation and an effective optimal in pit / multi-pit blending scheme.